Proppant Flowback Control

Proppant Flowback Control

-

Sand production will often increase with increased water cut from a well. Desanders or filtration equipment is required to remove the sand at the well head. Sand production in the early stages of the well are usually a result of sand flow back from a …

Sand production will often increase with increased water cut from a well. Desanders or filtration equipment is required to remove the sand at the well head. Sand production in the early stages of the well are usually a result of sand flow back from a fracturing treatment.

Sand and fines plug downhole screens and reduce porosity of proppant packs. The fines accumulated in the well bore resulting in more cost due to frequent work-overs to improve production.

Production will typically be set at the Maximum Sand Free Rate (MSFR) to minimize the problems associated with sand production.

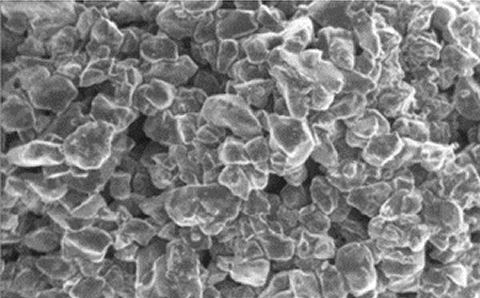

SandLock-11 adsorbs on sands and other solids in a system, altering the surface charges so the particles attract each other. Surface charges are unbalanced so that there are both attractive and repulsive charges between sand particles. This results in adhesion of sand particles with sufficient open spaces to not diminish permeability.

FEATURES AND BENEFITS

?Increases the rate of fluid load recovery after frac jobs

?Prevent flow back of the proppants when recovering the frac fluid

?Prevents sands from migrating to production screens, and plugging the screens

?Establishes a pliable, porous matrix that increases permeability of sandstone formations and/or sand packs. The permeability will not be reduced by shifts in the formation, because the matrix will move with the formation without breaking up

Appearance | Brown liquid |

Density, 20℃, g/cm3 | 1.00 |

pH | 6 |

Flash point, ℃ | >100 |

Solubility | Slightly soluble in water |